If you are building a new home in the near future, you may want to consider what type of foundation you’re going to install. The most popular foundation system in America is the poured wall. In the past, block walls have also been used excessively. There is a new kid on the block: precast concrete. There are a handful of manufacturers in the United States that produce these types of building foundations for residential and commercial use.

This phenomenon is catching on among enthusiastic homeowners looking for alternatives to traditional building practices. But what do we know about precast wall systems? How do they compare with traditional foundations? Are there specific advantages or disadvantages of using either product? The foundation is a big part of the home building process, and it is something that cannot be changed once installed.

The concept of the poured wall system is efficiency. It has superior drainage qualities and is set up to finish your basement immediately. Though brands may differ slightly, generally the walls are composed of a 2” thick concrete face on the exterior poured against a rigid foam insulation board sandwiched between the outer face and the concrete (steel reinforced) studs 24” on center. The bottom and top plate transfer the load to the footing, which is composed of crushed rock. The crushed rock footing allows for water drainage from under the slab to the exterior tile. For more information on a local installer, visit the Superior Walls website.

In 2009, I had the golden opportunity to compare both types of foundations on the same exact house. We built two houses in 2009 that had the same footprint (although the floor plans were slightly different); one in the spring, one in the fall. We installed the precast system in March, and the poured wall for the similar house was installed in August. The results of the comparison both surprised and educated me.

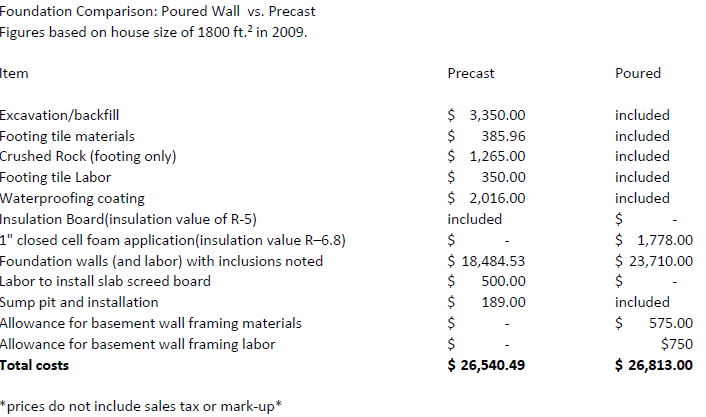

The cost is usually the main consideration of the homeowner when comparing two different products. The following table breaks down the cost differences:

As evidenced by the numbers, there is very little difference in the price. On these two jobs several items need to be considered. In 2010, the state of Illinois adopted a new energy code, the International Energy Conservation Code (IECC) which now requires basements to be insulated to a value of R-10 in climate zone five (where East Central Illinois is located). The particular manufacturer that we have used in the past, Superior Walls, has a standard wall system with the value R-5 and their “xi” version which has an R value of R–12.5. In 2009 before the code was passed, we used the R-5 system for the precast and sprayed a 1” layer of closed cell foam on the poured wall site. Neither of these options would pass today.

In addition, because of today’s emphasis on the energy code, building officials are now paying extra attention to key areas of the house, including the basement walls. Now with the demand for mandatory insulation on the walls, the issue of fire resistance comes into play. Most foam products do not have the necessary smoke and flame spread ratings needed to be left exposed, so a fire barrier of some sort must shield both the rigid foam board on the precast system and the spray applied foam on the poured wall. There are several options out there, including thermal blankets and fiberglass insulation, but the most sensible option when you start comparing costs and products is to just finish the basement walls with drywall, something that is going to begin to catch on as this new code is enforced. Homeowners who once considered whether or not they were going to finish the basement down the road now no longer have that option.

With all that taken into account, let’s look at the comparison:

- Installation – precast walls can be completed quickly – often in just a day or two and are not as susceptible to weather delays

- Precast walls are poured in a factory setting, assuring the quality of cement mix (no extra water is added on site, which can weaken the concrete)

- Precast walls are typically poured at a higher psi – around 5000. Poured walls are a lower 3500 psi. However, the poured wall is solid throughout rather than 24” on center, so it doesn’t need the stiffer mix necessarily.

- Pea gravel footing of precast option allows for superior drainage. Rising water under the basement slab can flow to the footing tile through the crushed rock footing. On a poured wall system, water has to get around the concrete footing to reach the tile, which builds pressure, or flow into a secondary tile inside the footing to get out.

- Certain soil types that are weaker (sandy, silt) are not ideal for precast applications.

- Precast systems are relatively new in the residential field and homeowners, building officials, flatwork contractors, and builders alike are skeptical of them. Builders may charge more to build on a precast system because of the learning curve. There are a few minor extra steps that must be taken (mainly additional bracing and a delay in backfill) with the precast system that will increase the labor costs from the builder. Do your homework and choose a builder that has experience with the precast system installation, or you may pay for it.

- Use of a precast system requires a little more coordination on the part of the general contractor, including scheduling rock delivery, flatwork, excavation and tile work.

- Precast option reduces the chance for stress cracks in the wall system with controlled joints in the panels, but relies heavily on sealant to keep water out

- Precast options may come with a warranty. Superior Walls carries a 15 year limited warranty. Poured walls usually do not have a guarantee.

- Precast walls are pre insulated and ready for drywall. The concrete studs have holes to accommodate plumbing and electrical.

- Precast advocates boast that since the walls are poured square at the factory, the final product is guaranteed to be plumb, level, and square. However, as with any product, installation can make it or break it. We have built on both precast and poured walls numerous times, and there is no guarantee that either product is superior in this regard.

- Precast walls are steel reinforced. Many times poured walls are not, especially in areas where the building code is not enforced.

A sound investment takes much thought and planning. Making the right call on your foundation is a big decision. Do your homework, go out and look at different foundations, talk to the people that live in those houses, talk to an experienced contractor, and think about your future carefully. Then make an educated choice knowing you can sleep at night because you gave yourself the best possible situation to make your mind up in.

For a detailed quote on a foundation for your new home contact us today.